- #Stepper motor driver controller drivers#

- #Stepper motor driver controller full#

- #Stepper motor driver controller pro#

#Stepper motor driver controller full#

We stock a full range of stepper motors that are designed to help your application run smoothly and efficiently. Why choose Allied Electronics for your stepper motors? They’re also used in motorized camera sliders and allow for very smooth operation of camera-positioning rigs.

#Stepper motor driver controller drivers#

Stepper motor drivers are often used in high-end cameras because of the need for extreme internal precision with in-lens autofocus and aperture settings. This is because a 3D printer needs to be highly accurate and a stepper motor is a cost-effective way of achieving that precision. In 3D printing for example, stepper motors are very common.

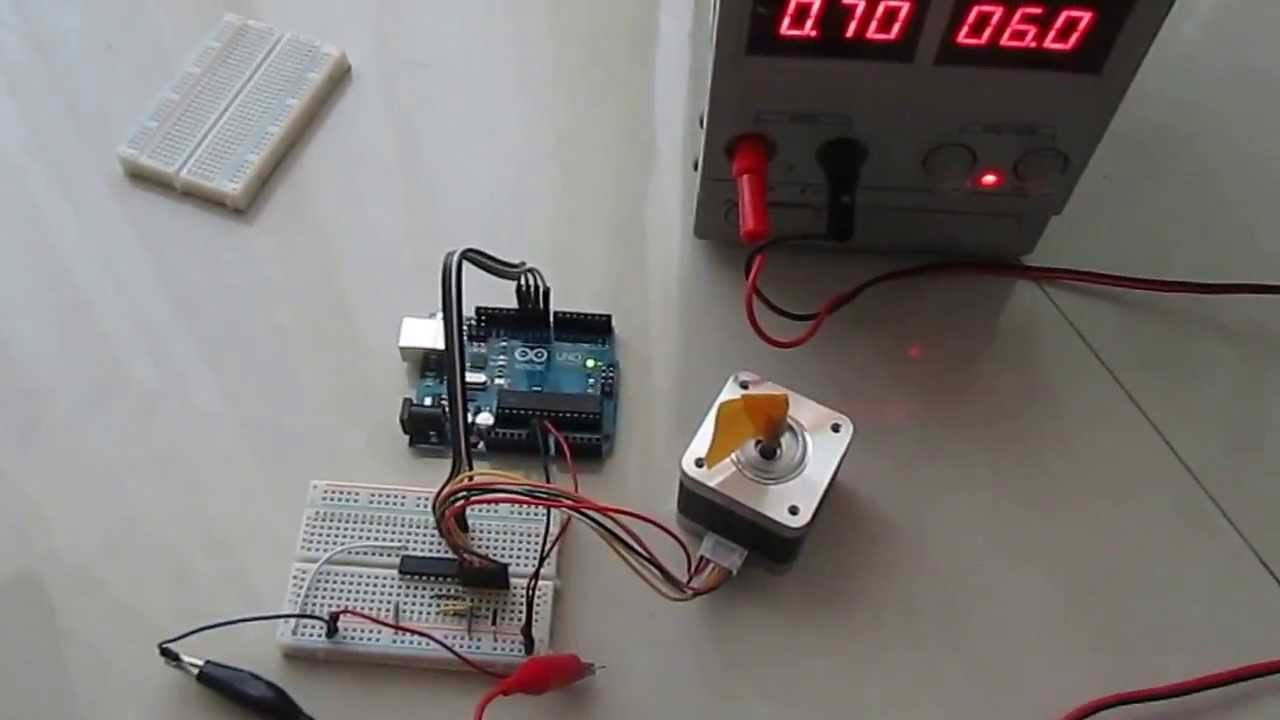

One of the biggest advantages is that they’re relatively low cost. There are a number of advantages for choosing stepper motors for your project. They’re most commonly used in holding or positioning machines, where their ability to make clearly defined rotational positions, speeds and torques makes them ideally suited to rigorous movement control. Stepper motors have been designed to be digitally controlled and function as a key component in a motion-control system. Instead, they’re designed for precision starting and stopping in an application. Unlike other types of electric motors, a stepper motor doesn’t just rotate continuously for a random number of spins until it’s shut off. As the digital pulses increase in frequency, the step movement changes into continuous rotation. Stepper motors are digital input-output devices that send a digital pulse to a stepper motor driver, causing the motor to perform one precise angle of motion. Read on for more information on stepper motors, their benefits and all the different applications they can be used for.

#Stepper motor driver controller pro#

We have a full selection in stock from brands including Schneider Electric, Crouzet, RS Pro and Nidec Motors, so you can rest assured you’re buying the highest quality products for the project you are working on. Well suited to applications where control signals appear as digital rather than analog voltages, they’re often found in robotics, machine tools and picking machines.Īt Allied Electronics, you will find hundreds of products in the stepper motors range, including stepper motor drivers and stepper motor controllers. Simply put, stepper motors are brushless, synchronous electric motors that convert digital pulses into mechanical rotation.

0 kommentar(er)

0 kommentar(er)